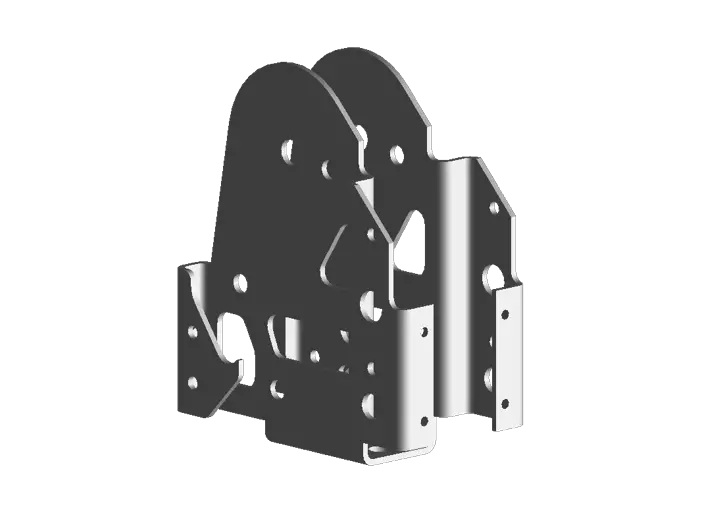

Many engineers developing 3d models for sheet metal products are unaware of the fabrication tools used to form the part or product and instead design models for an ideal world.

Fundamentals of sheet metal design.

Unfortunately some creators of sheet metal enclosures and assemblies do not design with the.

Distance from the bend to the hole edge should be equal to or more than twice the thickness of the sheet.

Design for manufacturability is now a common concept in many industries including the sheet metal design sector.

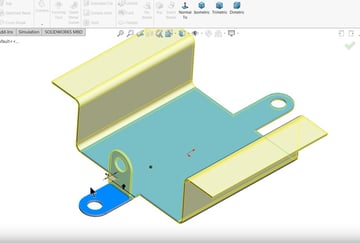

Bends in sheet metal are manufactured using sheet metal brakes.

In the ideal.

Whether you are fabricating military equipment or automobile parts it s essential to follow the stipulated guidelines.

Let s take a look at some examples.

The minimum hole diameter should be equal to or more than the sheet thickness.

There are two images below that show the correct bend radius for a 1 mm thick sheet top and the correct bend orientation for two bends in the same plane bottom.

Few thumb rules or sheet metal design fundamentals.

We would like to show you a description here but the site won t allow us.

To meet unique sheet metal design challenges like manufacturability solid edge streamlines the entire sheet metal product development process from cad design through flat pattern and drawing development.

Sheet metal can be cut bent and stretched into an amazing array of shapes.

A 1 degree tolerance on all bend angles.

For more information on sheet metal fabrication download our sheet metal design guide here.

Sheet metal design is key to the production of quality products.

Sheet metal parts with a minimum of 0 9mm to 20mm in thickness can be manufactured.

When designing parts for laser cutting one should not make holes smaller than the thickness of the material.

Learn more about protocase what we make who we work with our simple design processes and advanced design tools and our 2 3 day manufacturing process.